Understanding the Modern Folding House Container Concept

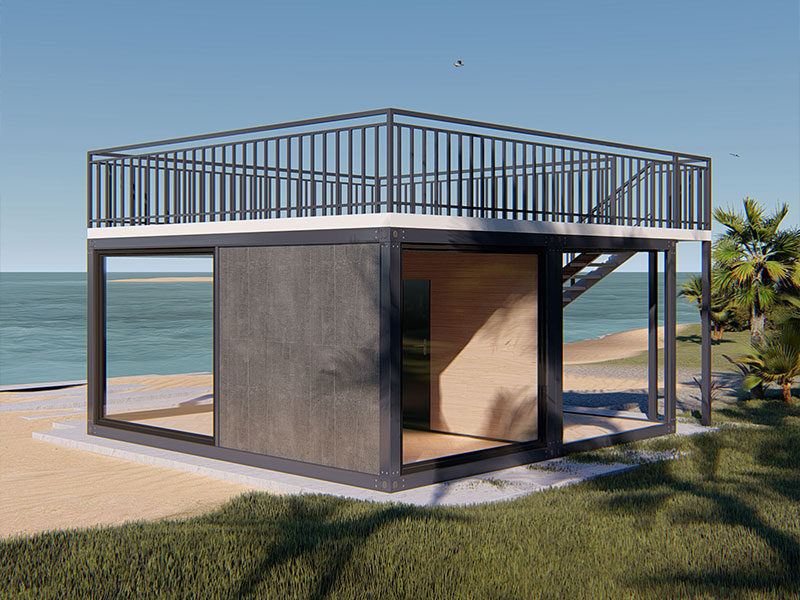

The architectural and construction landscape is continuously evolving, driven by the need for efficiency, sustainability, and adaptability. Within this dynamic environment, the concept of the folding house container has emerged as a revolutionary solution, ingeniously merging the robustness and modularity of shipping containers with transformative mobility and space-saving design. At its core, a folding house container is a pre-fabricated living or working unit constructed from durable materials, typically steel frames with high-quality cladding, engineered to be compactly folded for effortless transportation and rapidly deployed on-site. This innovation addresses critical challenges in temporary housing, emergency shelters, remote site offices, and even contemporary permanent dwellings. Unlike static structures, these units offer unparalleled flexibility, allowing them to be easily relocated, reconfigured, or stored as needs change. The integration of container architecture with folding mechanisms represents a significant leap forward in portable construction, offering a practical answer to global issues such as rapid urbanization, disaster response, and the demand for cost-effective, high-quality building solutions. As industries and individuals seek smarter ways to build, the folding house container stands out for its promise of reducing logistical complexity, minimizing on-site construction waste, and accelerating project timelines, all while maintaining structural integrity and comfort.

Five Key Long-Tail Keywords for Folding House Container Exploration

To delve deeper into this niche, certain specific queries reflect genuine user intent and present opportunities for targeted information. These long-tail keywords combine reasonable search volume with lower competition, making them ideal for focused content. They are: affordable folding container homes for rural areas , collapsible shipping container office design plans , weather resistant foldable house containers for temporary shelter , DIY expandable container cabin kits and installation , and lightweight folding mobile homes for frequent relocation . Each phrase captures a distinct application, concern, or user scenario, guiding the comprehensive discussion that follows and ensuring the content resonates with the varied needs of potential clients and enthusiasts in this field.

In-Depth Analysis of Folding House Container Applications and Comparisons

Affordable Folding Container Homes for Rural and Remote Deployments

The application of affordable folding container homes for rural areas is transforming access to quality housing in locations where traditional construction is logistically challenging or prohibitively expensive. These units are specifically engineered to offer a balance between cost-efficiency and durability, making them ideal for agricultural worker housing, hunting lodges, eco-tourism resorts, or permanent residences in off-grid settings. The primary advantage lies in the significant reduction of transportation costs; since the structure folds into a compact volume, multiple units can be shipped in a single trip compared to pre-assembled modules. This directly translates to lower overall project costs for the end-user. Furthermore, their design often incorporates considerations for basic utilities, allowing for integration with septic systems, solar power, and rainwater harvesting, which are common in rural environments.

When comparing traditional rural construction to folding container solutions, several key differences emerge. Traditional brick-and-mortar or wooden frame houses built on-site require a sustained presence of skilled labor, reliable access to material suppliers, and are highly susceptible to weather-related delays. The foundation work alone can be time-consuming. In contrast, a folding container home arrives as a near-complete unit. The site preparation is simplified, often requiring a level gravel or concrete pad. The deployment process, which involves unfolding, securing, and connecting utilities, can be completed in a matter of days, not months. This speed is crucial in rural settings where construction seasons may be short or where immediate housing is needed. The controlled factory environment where these units are manufactured, such as at Wujiang Hongchang Color Plate House Factory, ensures consistent quality. Every component, from the steel frame to the insulation and interior finishes, is assembled under strict protocols, eliminating the variability often seen in remote site construction. This results in a product that is not only affordable in terms of initial and logistical costs but also reliable and long-lasting, with predictable performance in insulation and structural safety.

Traditional Rural Home vs. Folding Container Home : A Side-by-Side Look

The following table highlights the fundamental contrasts between constructing a traditional home in a rural area and opting for a folding container home solution.

| Factor | Traditional Rural Construction | Affordable Folding Container Home |

|---|---|---|

| Construction Time | Several months to over a year, depending on weather and labor. | Site prep in days; unit deployment and locking in 1-3 days. |

| Labor Dependency | High dependency on skilled local labor, which may be scarce. | Minimal on-site labor required; primarily needs a small crew for placement and connection. |

| Transportation Logistics | Multiple deliveries of bulk materials (lumber, concrete, bricks) required on often difficult roads. | Single, compact delivery of the folded unit, easier to transport on standard trailers. |

| Cost Predictability | Prone to cost overruns due to material price fluctuations, weather delays, and unforeseen site conditions. | Fixed manufacturing cost; primary variables are site preparation and utility hookups, leading to better budget control. |

| Quality Control | Quality depends on subcontractor skill and on-site supervision, which can be inconsistent. | Quality is assured in a factory setting with standardized processes and rigorous inspection, like those at Wujiang Hongchang Color Plate House Factory. |

| Weather Resistance During Build | Exposed materials and structures are vulnerable to rain, wind, and temperature during the long build phase. | The structure is manufactured indoors and is only exposed briefly during deployment, minimizing weather risk. |

Designing Functional Spaces: Collapsible Shipping Container Offices

The demand for flexible, professional, and quickly deployable workspaces has made collapsible shipping container office design plans a critical topic for construction managers, event coordinators, and growing businesses. These are not mere site sheds; they are fully-fledged offices designed for productivity, equipped with lighting, electrical systems, climate control, and interior finishes that meet commercial standards. The design philosophy centers on maximizing usable space within the compact container footprint while ensuring the structure can reliably fold and unfold without compromising the integrity of these interior systems. Effective plans often feature large windows for natural light, strategic placement of doors for access and safety, integrated cable management for IT equipment, and efficient layouts that may include a reception area, private offices, and a small meeting space.

A key aspect of these designs is their adaptability. A standard 20-foot or 40-foot container office can be a single, self-contained unit, or multiple units can be combined to create larger office complexes, conference centers, or classroom facilities. The collapsible nature means a company can lease a piece of land for a short-term project, deploy a fully-functional office within a week, and then remove it just as easily once the project concludes, leaving the site undisturbed. This eliminates the need for costly permanent structures for temporary needs. From a manufacturing perspective, creating such sophisticated foldable units requires a high degree of engineering precision. The hinge mechanisms, electrical conduit connections at fold points, and seal integrity must be flawless. Factories with strong R&D capabilities, such as Wujiang Hongchang Color Plate House Factory, invest significantly in designing these critical interfaces. Their professional inspection teams rigorously test each unit's folding action and environmental sealing to ensure that the office remains a secure, weatherproof, and professional environment through numerous deployment cycles, thus protecting the valuable equipment and personnel inside.

Core Design Considerations for a Collapsible Container Office

- Structural Integrity: The frame must withstand repeated folding/unfolding cycles. High-tensile steel and reinforced corners are essential.

- Utility Integration: Electrical wiring, HVAC ducts, and data cables must have flexible connections or quick-disconnect points at the folding joints to prevent damage.

- Interior Layout Efficiency: Space planning must account for fixed elements like restrooms or server racks that cannot cross fold lines, optimizing the remaining area for workstations.

- Compliance and Safety: Designs must adhere to local building codes for commercial spaces, which may include regulations for emergency exits, fire-rated materials, and accessibility.

- Aesthetic and Professional Appeal: Exterior cladding (like the color plate from specialized factories) and modern interior finishes are crucial to project a professional image, moving beyond the industrial container look.

Ensuring Durability in Demanding Environments

A paramount concern for any portable structure is its ability to withstand the elements, making the topic of weather resistant foldable house containers for temporary shelter especially vital. These shelters are often needed most in harsh conditions—as emergency housing after natural disasters, as field hospitals, or as base camps in extreme climates. Therefore, their design and manufacturing specifications must exceed those of standard temporary buildings. Weather resistance encompasses protection against rain, snow, wind, dust, and significant temperature fluctuations. Achieving this in a unit that also moves and folds is an engineering challenge that demands premium materials and meticulous craftsmanship.

The first line of defense is the external cladding. Corrugated steel sheets with high-quality paint systems or aluminum composite panels are common choices, offering excellent durability and corrosion resistance. Factories specializing in this field, like Wujiang Hongchang Color Plate House Factory, enforce strict raw material selection and auditing. The steel used for the frame and walls is often galvanized or coated to prevent rust. Sealing is the most critical component. All seams, especially around the folding mechanisms, doors, and windows, must be sealed with high-grade, flexible gaskets and sealants that remain effective through temperature changes and physical movement. The roof design typically incorporates a slight pitch to ensure water runoff and prevent pooling. Additionally, insulation is not just for comfort but also for preventing condensation inside the walls, which can lead to mold and structural degradation. High-density foam or rockwool insulation is installed within the wall cavities during factory assembly, ensuring complete coverage and thermal break. This controlled factory process guarantees that the insulation is dry and perfectly fitted, a standard far harder to achieve with on-site assembly in adverse weather. The result is a shelter that provides a safe, dry, and thermally stable environment regardless of external conditions, a crucial factor for humanitarian aid and critical operations in remote locations.

From Kit to Home: The DIY and Professional Installation Pathway

The growing interest in self-sufficiency and custom projects has fueled the market for DIY expandable container cabin kits and installation . These kits cater to hands-on individuals who want to be involved in creating their own space but benefit from the engineering and precision of a pre-designed system. A typical kit includes all the major structural components—pre-fabricated wall, floor, and roof panels with integrated folding mechanisms, windows, doors, and all necessary hardware and fasteners. It may also include pre-cut utility chases and connection points for electrical and plumbing systems. The appeal lies in the balance between customization and guidance; the buyer handles the on-site foundation preparation, the unfolding and assembly process, and the interior finishing, but does so with components designed to fit together perfectly.

However, it is crucial to understand the spectrum of involvement. A full DIY kit assumes the owner has significant construction skills, tools, and the ability to manage utility connections, which often require licensed professionals for safety and code compliance. On the other end, many providers offer a hybrid model where the factory supplies the kit and an installation manual, but also provides the option for professional on-site supervision or turnkey installation services. For a manufacturer, producing such kits requires an even higher level of documentation, packaging, and quality control. Each part must be clearly labeled, and instructions must be exhaustive to prevent errors that could compromise the structure's safety or weatherproofing. The commitment to quality demonstrated by manufacturers like Wujiang Hongchang Color Plate House Factory, with their traceable batch production and stringent final inspection, is particularly valuable in the DIY kit context. It gives the customer confidence that the complex components they are receiving are reliable and will perform as intended, reducing the risk of costly mistakes during the build. Whether fully self-installed or contractor-assisted, these kits empower users to create a personalized foldable cabin while leveraging industrial-grade manufacturing quality.

Optimizing for Mobility: Lightweight Solutions for Nomadic Lifestyles

The concept of lightweight folding mobile homes for frequent relocation addresses a specific and growing demographic: digital nomads, traveling healthcare workers, seasonal contractors, and those embracing a minimalist, location-independent lifestyle. For these users, the ability to relocate their home easily, quickly, and affordably is as important as the home's features. Weight becomes a primary design constraint because it directly impacts towing requirements, fuel consumption during moves, and the types of vehicles or permits needed. Designing a lightweight yet durable and comfortable folding home is a sophisticated task that involves material science and clever engineering.

Traditional shipping containers are incredibly strong but heavy. Modern folding mobile homes often utilize lighter but high-strength materials for the frame, such as specially engineered aluminum alloys or high-strength, lightweight steel. The wall and roof panels might employ composite sandwiches—two thin, strong skins (like fiberglass or aluminum) bonded to a lightweight core (like polyurethane foam). This provides structural rigidity, insulation, and a finished surface in one lightweight component. The folding mechanism itself is designed to be as light as possible, often using aircraft-grade aluminum components. Every system inside is also optimized for weight: compact appliances, modular furniture, and thin but efficient insulation. The goal is to create a home that meets all living needs—sleeping, cooking, hygiene, and working—while staying below critical weight thresholds for easy towing with a standard heavy-duty pickup truck. This portability does not mean a sacrifice in quality. In fact, the precision required to build a reliable, lightweight foldable home is immense. The production process must ensure perfect alignment so the unit folds smoothly without binding, and all seals mate perfectly every time. The rigorous production control and supplier quality monitoring practiced by established manufacturers ensure that the use of advanced lightweight materials does not come at the expense of the product's stability or longevity, providing a truly mobile and dependable living solution.

The Integral Role of Specialized Manufacturing in Folding Container Quality

The reliability, safety, and performance of any folding house container are fundamentally rooted in its manufacturing process. This is where concepts and designs are translated into tangible, functional products. A specialized factory brings indispensable value to this ecosystem through structured systems for research, quality control, and production efficiency. Wujiang Hongchang Color Plate House Factory exemplifies this approach, operating with a dedicated R&D team that focuses on innovating and refining folding mechanisms, material applications, and space-efficient designs based on market feedback and specific customer blueprints. This capability allows for customization while maintaining engineering integrity.

More importantly, such a factory institutes a culture where quality is the unequivocal priority. This philosophy is operationalized through several key practices:

- Stringent Raw Material Management: The foundation of a durable product is superior raw materials. This involves careful selection and auditing of suppliers for steel coils, paint systems, insulation, sealants, and hardware. Incoming materials are subjected to testing and comparison against specifications to prevent substandard components from entering the production line.

- Advanced Process Design and Control: Top-tier production process design ensures each step—from cutting and framing to welding, panel assembly, insulation injection, painting, and final assembly—is optimized for consistency and precision. This controlled environment makes each batch of products stable and their quality traceable back to specific production parameters and material lots.

- Comprehensive Inspection Regimes: A professional inspection team is integrated throughout the manufacturing journey, not just at the end. They monitor critical stages, such as the integrity of welds on the folding hinge points, the application of seals, the installation of electrical wiring, and the final function test of the folding operation. This multi-layered inspection ensures every unit that leaves the facility meets rigorous performance and safety standards.

This holistic, system-driven approach to manufacturing is what transforms a simple idea for an affordable folding container home for rural areas or a weather resistant foldable house container for temporary shelter into a dependable reality. It provides the assurance that the product will perform as intended through countless folds and unfolds, in harsh weather, and over many years of use, ultimately delivering on the core promises of flexibility, durability, and value that define the folding house container market.